Anyone responsible for producing printed materials -whether in a school reprographics room, a corporate print facility,

or a marketing department – knows that consistency matters. When documents need to look sharp on the first run, the choice of paper becomes just as important as the capabilities of the printer itself. This is where ColorLok® Technology offers a practical and reliable advantage.

What Colorlok® Technology Brings to Everyday Printing

ColorLok® Technology is a print-quality performance standard, engineered to deliver noticeably better results on plain paper. When paper carries the ColorLok® mark, it has met specific criteria designed to improve the density of black text, enhance colour vibrancy and shorten drying times. These improvements benefit high-volume environments, especially where fast turnaround and professional output are essential.

Many global mills and merchants license ColorLok® Technology, so it appears across a broad range of paper brands. This helps departments maintain quality even when sourcing paper from different suppliers.

How the Technology Works in Real Print Settings

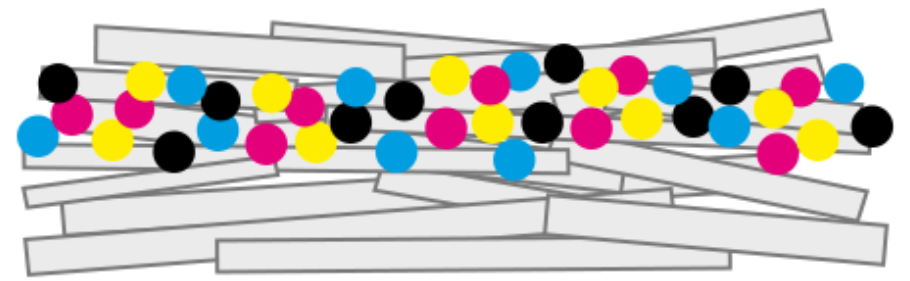

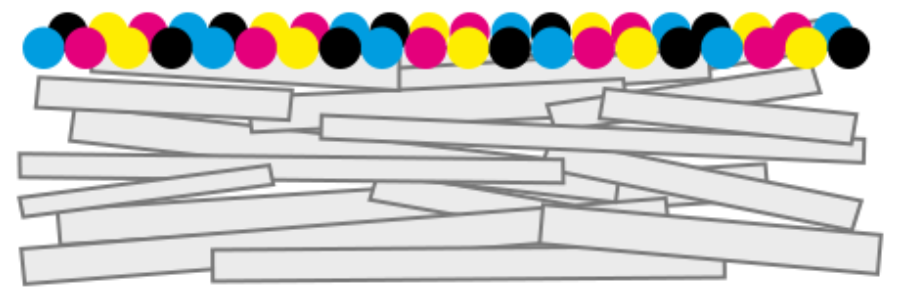

During manufacturing, a chemical additive is built into the paper to hold pigment particles near the surface. Because this reaction happens instantly when ink hits the page, colours remain vivid and edges stay clean. In contrast, standard paper allows pigment to sink deeper into its fibres, which often leads to softer blacks and washed-out graphics.

For inkjet printers, this surface-level retention makes a noticeable difference. For instance, marketing teams printing sample packs or internal proofs often remark on how much richer imagery appears on ColorLok® certified paper. Similarly, school reprographics teams find that worksheets and booklets dry quickly enough to handle immediately, reducing the risk of smudging when stacking large batches.

Laser devices also benefit. While toner works differently from ink, the smoother, more consistent sheet characteristics of ColorLok® papers help maintain clarity and reduce background mottling on text-heavy documents.

Standard Paper vs. Colorlok® Paper in High-Demand Environments

In busy print rooms, small variations in paper performance can result in lost time or reprints.

Standard paper often absorbs ink unevenly, causing feathering along text edges. This becomes particularly noticeable on timetables, policy documents, instruction sheets, and other materials

requiring clear readability. Colour-rich items – such as marketing proofs or

student posters – also come out flatter on standard paper.

ColorLok® paper keeps pigments on the surface long enough to deliver stronger saturation, improving the impact of both photographs and

graphic elements.

When consistency is part of your service promise, this level of reliability helps maintain professional standards without upgrading hardware or changing workflows.

Making the Most of Colorlok® Paper

Because ColorLok® Technology is available across multiple grades and suppliers, managers can select the weight, brightness and finish that best fit their needs without sacrificing print quality. It integrates easily into existing stock management and works across all common office and production devices.

For teams looking to reduce waste, improve turnaround or simply present clearer, more compelling documents, ColorLok® certified paper provides a straightforward improvement with immediate results.

Ready to Improve Your Print Quality?

If you’d like guidance on choosing the right ColorLok® certified papers for your print room or want help testing options across your devices, get in touch. A small change in paper choice can make a significant difference in day-to-day output.

Look out for ColorLok® logo on our certified ProDesign and PaperOne papers in our shop 👉 Click here.